What are the different types of industrial shock absorbers?

Shock absorbers aren’t just for cars—they’re also widely used in industrial, defense, medical, civil engineering, and automation applications to protect machinery, structures, and people from sudden forces, vibrations, or impacts.

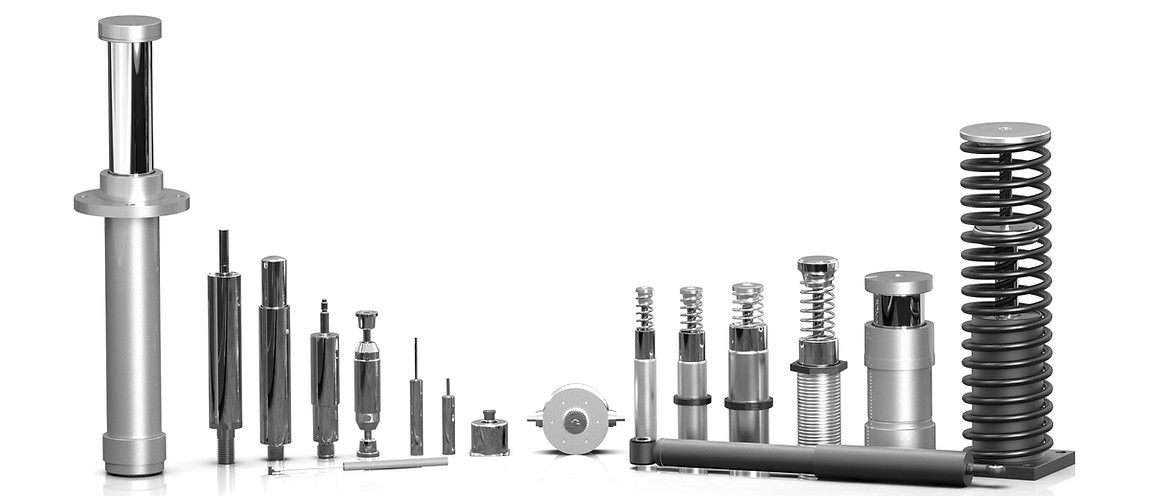

Here are some common types of industrial shock absorbers and damping systems:

-

Hydraulic Shock Absorbers

These use oil (hydraulic fluid) to slow down and stop moving parts smoothly. The fluid is forced through small holes (called orifices), which creates resistance and converts kinetic energy into heat.

-

Crane Buffers / Heavy-Duty Buffers

Installed on cranes and heavy machinery, they absorb large impacts when equipment stops moving to protect the structure and reduce wear.

-

Recoil Buffers

Specialized dampers used in defense systems to absorb the recoil force when firing large guns or artillery, making them safer and easier to handle.

-

Viscoelastic Dampers

These use special materials that deform under load and slowly return to shape. They are often used in buildings and bridges for seismic protection to absorb earthquake energy.

-

Miniature / Compact Shock Absorbers

Small, precision shock absorbers for robotics, automation, packaging machinery, and medical devices to ensure delicate parts don’t get damaged during movement.

-

Seismic Dampers / Structural Dampers

Installed in tall buildings, bridges, and other civil engineering structures to absorb the energy from wind, earthquakes, or vibrations and keep the structure stable.

Each of these types is designed for specific conditions: size, load, speed, and environment.

How does a shock absorber actually work?

Imagine something moving very fast—like the arm of a robot, a sliding gate, or a heavy load on a crane. When it suddenly stops, the energy it carries could damage the machine or structure. A shock absorber’s job is to “absorb” this energy gently so the movement stops smoothly rather than abruptly.

Here’s how it typically works:

-

Inside a hydraulic shock absorber, there’s a piston moving inside a cylinder filled with oil.

-

When the piston moves (because of an external force), oil is pushed through small holes (orifices) or valves inside the piston.

-

These holes are so small that the oil can’t rush through quickly; it meets resistance.

-

This resistance slows down the piston’s motion, turning the kinetic energy into heat energy in the oil.

-

By carefully designing the piston and orifice sizes, engineers control how fast the shock absorber reacts and how much force it can handle.

The main concept is:

Convert kinetic energy (movement) → into heat → through controlled fluid flow → which stops the movement safely.

Have more questions? Email us at info@shockbuffer.com