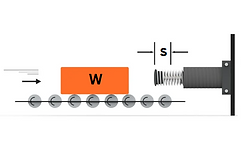

Sizing Industrial Shock Absorbers for

Mass on Moving Rollers

In conveyor systems and material handling lines, products and pallets often move along powered rollers, sometimes reaching considerable speeds and carrying significant weight. At Shockbuffer, we provide specialized industrial shock absorber selection and sizing of shock absorbers for these roller-driven applications to control stopping forces and prevent damage at end stops. Our medium industrial shock absorbers are designed to absorb the kinetic energy of moving loads on rollers, reduce impact, and extend the life of mechanical systems. Using the right shock absorber for machinery helps protect conveyor equipment, improve safety, and keep production running smoothly

Formulae

E1 = W · v · 0.5

E2 = W · μ · g · s

E3 = E1 + E2

E4 = E3 · c

vD = v

We = (2 · E3) / vD

2

2

Example: Sizing Industrial Shock Absorbers for Mass on Moving Roller.

W = 400 kg

v = 1.25 m/s

c = 100 /hr

μ = 0.2

s = 0.025 m

E1= 400 · 1.25 · 0.5 = 312.5 Nm

E2 = 400 · 0.2 · 9.81 · 0.025 = 18.1 Nm

E3 = 312.5 + 18.1 = 330.6 Nm

E4 = 330.6 · 100 = 33060 Nm/hr

We = (2 · 330.6) / 1.25 = 423.2 kg

2

2

Applications of Industrial Shock Absorbers

Typical shock absorber applications in this category include:

-

End-of-line conveyor stops where pallets or boxes must stop gently

-

Roller conveyors moving heavy cartons or containers in distribution centers

-

Pallet handling systems with motor-driven rollers and automated stops

-

Accumulation conveyors where multiple products line up and need controlled buffering

-

Transfer stations where items roll from one conveyor section to another

-

Heavy-duty packaging lines handling large or fragile goods on roller beds

In all these cases, a medium industrial shock absorber must be correctly sized to absorb the kinetic energy from the mass rolling on the powered conveyor, ensuring quiet, smooth, and controlled stopping.

Have more questions? Email us at info@shockbuffer.com